- ProductsProducts

- FacadesEnvelop your space with sidelighting.

- Skyroofs®

Elevate your whole space with monumental toplighting.- Skylights

Elegant and economical toplighting.- Canopies

Enhance transitional spaces and provide excellent wayfinding.- Benefits

Daylighting+ all the benefits you'll ever need.- Technology

Discover the technology behind perfect daylighting.Meet the last daylighting products you'll ever need.- Resources

Resources- LiteratureProduct brochures, market brochures and case study reports.

- Specs, CAD, BIMInsulated Translucent Sandwich Panel Daylighting Systems – Specifications. Section 08 45 23. CAD details and BIM families for products.

- Daylight Modeling

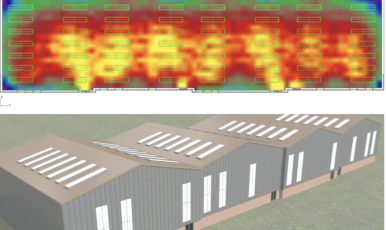

Daylight with confidence when you take advantage of 3D simulation to see how light interacts with a space.- Education Center

We are not simply here to sell a product. We are here to share knowledge.One stop shop for product information, on-demand webinars and other daylighting education. - Daylight Modeling

- Portfolio

- CompanyCompany

- AboutOur focus has always been innovative daylighting solutions for healthy, beautiful and sustainable buildings.

- History

- Innovation

- Kalwall CaresWe believe in giving back to the local community.

- CareersWe are a dynamic and growing company.

- BlogsStay up to date with Kalwall company news, product highlights and industry happenings.

Kalwall has been providing museum-quality daylighting™ for more than 65 years.- Contact

- About

Download Case Study

Download Case StudyCase Study

South Bend Regional Airport | South Bend, Indiana

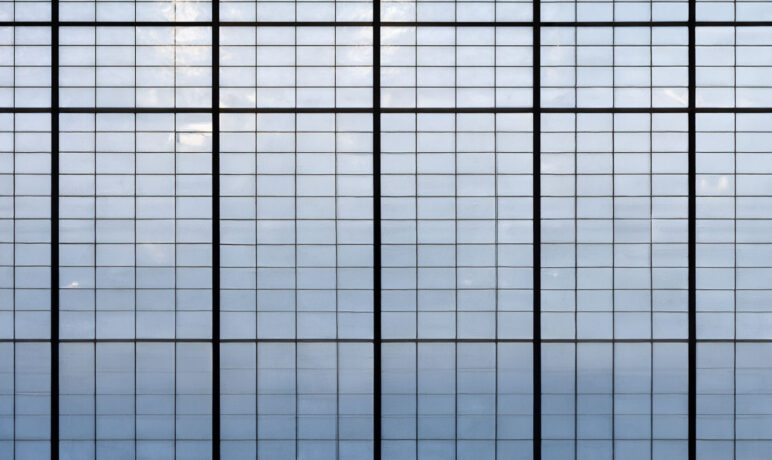

The terminal is a significant update for the regional airport with the latest in comfort and convenience. Concourse A is a new 45,000 ft2 expansion with 5 new gates, dining room, lounge, gift shop and a children’s room. “The new concourse consists of an architecturally exposed, steel-framed barrel vault structure that simulates the structure of an aircraft wing,” explains Wall. “Holes cut in the webs of the custom-engineered, curved, perforated (cellular) built-up plate girders and cellular purlins (SMARTBEAMS®) make the long structural elements visually and figuratively lighter as they arch over the concourse. The arch is raised on one side with a continuous north-facing clerestory and is topped with a custom-fabricated, curved translucent panel roof system by Kalwall, which bathes the concourse in natural light. After entering the concourse through the windowless security area the bright open space provides a welcoming waiting area.”

“We designed a translucent roof as a key element to the airport concourse,” continues Wall, “…we understood that Kalwall is the leader in the industry and has the track record to accommodate the design we needed. Kalwall was able to not only provide detailed product information, but they did a comprehensive light study of our design that enabled us to achieve the appropriate light level.” Kalwall has been an industry leader in daylight modeling innovation that allows architects to examine “what if” alternatives while they demonstrate to clients the impact daylight will have on their finished project. Kalwall’s proprietary Daylight Modeling service is site specific to each project and includes a comprehensive array of reports and demonstrations including 3D video modeling, which even shows what a designed space will look like during various times of day throughout the year.

The custom Kalcurve® Skyroof® is 35’ wide and 600’ long and has a 42’ radius. “Gone is the gray box of a terminal, with its food provided by vending machines and its entertainment by a Ms. Pac-Man video game,” said Dave Stephens of the South Bend Tribune in a local article. “In its place… is a cavernous light-filled space that looks and feels like a wing of a major metropolitan airport with flat screen monitors and food court service.” As also seen in many airports around the world, a curved Kalwall Skyroof fills the space with glare-free daylight. Kalwall is the most highly insulating, translucent building material in the world. In addition to the daylighting benefits, Kalwall represents the leading edge of energy efficiency and is ideal in airport applications, as it is also virtually maintenance-free. Normal rainfall cleans the panels and saves on the expense of washing clear skylights, which are constantly dirty in an airport environment due to the presence of jet exhaust.

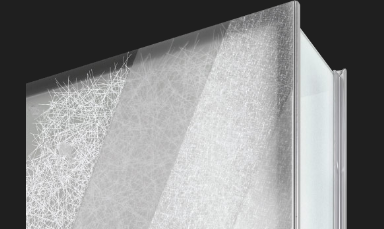

Translucent Kalwall building systems are also renowned for their ability to withstand high snow loads as well as hurricane force winds. Kalwall is also explosion resistant and Department of Defense security compliant which is another advantage for airports. “Kalwall provided support throughout design and construction phases. The light studies during design were invaluable to setting the correct parameters for the project. Having energy savings and natural light was a big draw to using a translucent roof. Because of the size of the roof area, the glass skylight we were considering was not acceptable for a number of reasons, including that it would let out too much heat. Kalwall’s R-value, while not as high as a solid roof, allowed us to have an acceptable level of insulation with the added benefit of natural light. Also the project includes a daylight harvesting system. Sensors turn off lights automatically based on the light level – saving energy used for artificial lighting.”

Construction took place in three phases over a 2-year period in order to allow the airport to operate with uninterrupted operation of all flights. The Kalwall Skyroof significantly contributed to this effort, as systems are pre-engineered and factory pre-fabricated for rapid installation. This speeds the construction process, lowers costs and results in leak-proof, trouble-free installation.

Specifications

Panel: 2.75″ | 70 mm

Grid core: shoji

Exterior FRP: white

Interior FRP: white

System finish: bone white #21b

U-Value: .22

Solar Heat Gain Coefficient: 0.15

Visible Light Transmission: 8%Take advantage of our complimentary daylight modeling services to understand how a Kalwall will impact your design.

Learn MoreThis website stores cookies on your computer. These cookies are used to collect information about how you interact with our website and allow us to remember you. By continuing using or registering on any portion of this site, you consent to our cookies and agree to our updated Privacy Policy, Cookie Policy and Terms of Use.Privacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.Cookie Duration Description _GRECAPTCHA 5 months 27 days This cookie is set by the Google recaptcha service to identify bots to protect the website against malicious spam attacks. cookielawinfo-checkbox-analytics 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". cookielawinfo-checkbox-functional 11 months The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". cookielawinfo-checkbox-necessary 11 months This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". cookielawinfo-checkbox-others 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. cookielawinfo-checkbox-performance 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". viewed_cookie_policy 11 months The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.Cookie Duration Description bcookie 2 years LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. bscookie 2 years LinkedIn sets this cookie to store performed actions on the website. lang session LinkedIn sets this cookie to remember a user's language setting. lidc 1 day LinkedIn sets the lidc cookie to facilitate data center selection. na_id 1 year 24 days The na_id is set by AddThis to enable sharing of links on social media platforms like Facebook and Twitter. ouid 1 year 24 days Associated with the AddThis widget, this cookie helps users to share content across various networking and sharing forums. UserMatchHistory 1 month LinkedIn sets this cookie for LinkedIn Ads ID syncing. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.Cookie Duration Description _ga 2 years The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. _ga_BSVJS87X9R 2 years This cookie is installed by Google Analytics. _gat_gtag_UA_19509828_3 1 minute Set by Google to distinguish users. _gcl_au 3 months Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. _gid 1 day Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. CONSENT 2 years YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. hwp_visit session This cookie is used for storing an ID for the newsletter popup to tell if this is a new visitor or a visitor that has already been to the site. uid 1 year 24 days This is a Google UserID cookie that tracks users across various website segments. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.Cookie Duration Description __ss 1 day This cookie is set by SharpSpring, a marketing automation platform. This is used for tracking visitors and form submissions. __ss_referrer 1 hour This cookie is set by SharpSpring, a marketing automation platform. This is used for tracking visitors and form submissions. __ss_tk 25 years This cookie is set by SharpSpring, a marketing automation platform. This is used for tracking visitors and form submissions. anj 3 months AppNexus sets the anj cookie that contains data stating whether a cookie ID is synced with partners. fr 3 months Facebook sets this cookie to show relevant advertisements to users by tracking user behaviour across the web, on sites that have Facebook pixel or Facebook social plugin. IDE 1 year 24 days Google DoubleClick IDE cookies are used to store information about how the user uses the website to present them with relevant ads and according to the user profile. IDSYNC 1 year This cookie is set by Yahoo to store information on how users behave on multiple websites so that relevant ads can be displayed to them. koitk 10 years This cookie is set by SharpSpring, a marketing automation platform. This is used for tracking visitors and form submissions. pa_crosswise_ts 2 years The pa_crosswise_ts cookie is set by Perfect Audience for advertising purposes based on user behavioural data. pa_google_ts 2 years The pa_google_ts cookie is set by Perfect Audience for advertising purposes based on user behavioural data. pa_openx_ts 2 years The pa_openx_ts cookie is set by Perfect Audience for advertising purposes based on user behavioural data. pa_rubicon_ts 2 years The pa_rubicon_ts cookie is set by Perfect Audience for advertising purposes based on user behavioural data. pa_twitter_ts 2 years The pa_twitter_ts cookie is set by Perfect Audience for advertising purposes based on user behavioural data. pa_uid 2 years This cookie is set by prfct.co. This cookie is used across the websites that use same ad network to display ads to the other advertisers in the network. pa_yahoo_ts 2 years The pa_yahoo_ts cookie is set by Perfect Audience for advertising purposes based on user behavioural data. personalization_id 2 years Twitter sets this cookie to integrate and share features for social media and also store information about how the user uses the website, for tracking and targeting. test_cookie 15 minutes The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. uuid2 3 months The uuid2 cookie is set by AppNexus and records information that helps in differentiating between devices and browsers. This information is used to pick out ads delivered by the platform and assess the ad performance and its attribute payment. VISITOR_INFO1_LIVE 5 months 27 days A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. YSC session YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. yt-remote-connected-devices never YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. yt-remote-device-id never YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. yt.innertube::nextId never This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. yt.innertube::requests never This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.Cookie Duration Description A3 1 year No description AnalyticsSyncHistory 1 month No description hwp_new session This cookie indicates if the newsletter pop up is new. li_gc 2 years No description - Skyroofs®

- Facades