1) Kalwall Weatherable Coating (KWS) technology aids in the panel’s self-cleaning properties and UV resistance.

2) The Bond Line between interior and exterior FRP face sheets and grid-core utilizes our proprietary adhesive technology.

3) Exterior Fiber-Reinforced Polymer (FRP) face sheet is color stable with a permanent glass veil erosion barrier to eliminate fiberbloom.

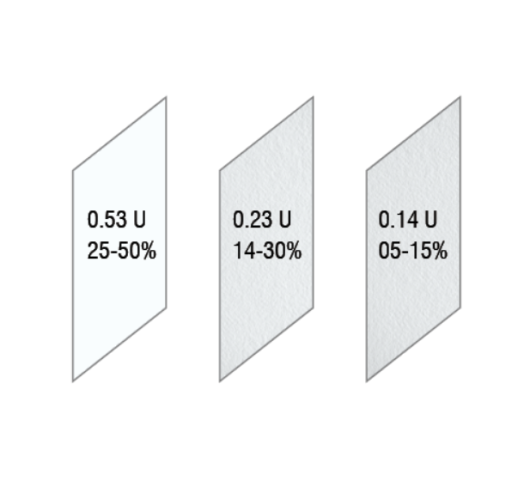

4) Translucent Insulation (TI) options offer exceptional thermal performance up to 0.05 U with Lumira aerogel.

5) Interior Fiber-Reinforced Polymer (FRP) face sheet formulated to meet finish, flame and smoke requirements of the toughest international codes.

6) Structural Grid Core composed of a series of interlocking aluminum and thermally broken I-beams.

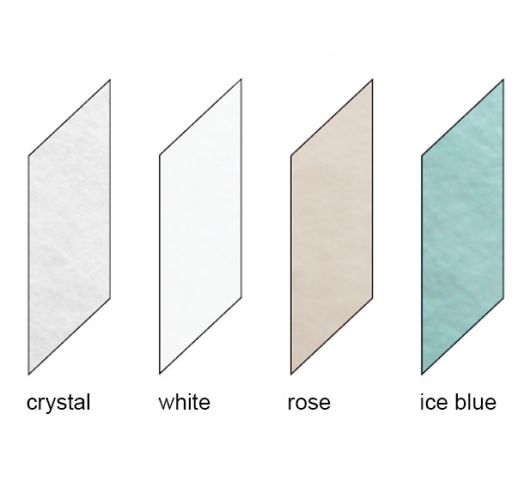

We produce a selection of translucent FRP to meet a wide range of project applications including specially formulated, exterior rated FRP as well as high impact, vandal resistant, UL and FM options. White and Crystal are standard. Kal-tints are optional.

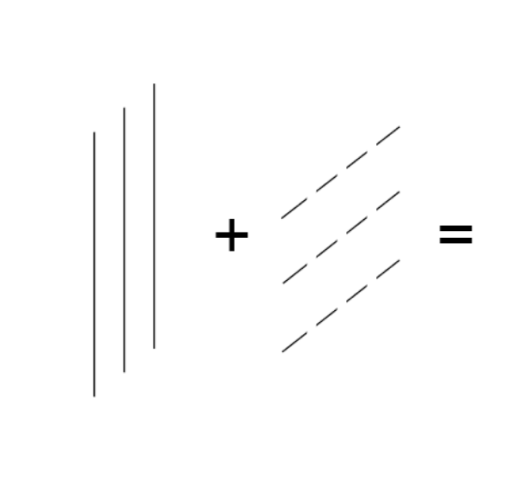

The Kalwall panel’s structural grid core provides strength while being extremely lightweight. That said, each core configuration performs differently. In general, more vertical mullions and tighter grids allow for longer spans and more panel stiffness. Both standard aluminum I-beams and thermally-broken interlocking I-beams are available.

Numerous translucent insulation options are available between 0.29-0.08 U-factor. For the most demanding applications, Kalwall offers a 0.05 U-factor (R-20) Lumira® aerogel option (available in 2-3/4″ thick panels only | limited grid-cores options available). TI specifications affect not only thermal performance but visible light transmission (VLT%) and solar heat gain control as well so please consult our sales team to optimize your design including our complementary daylight modeling services.